Products

Seamless Steel Line Pipe API SPEC 5L PSL1 & PSL2

Detailed Product Description

- Standard: API 5L Grade: B, X42, X52, X60, X65

- Size: 1/2" to 24" / SCH40 to SCH160, XXS

- Length: up to 40'

- PSL1&PSL2

Packing

- Packing in bundles

- Surface: Varnish coating / 3PE / FBE or Galv. coated

- Ends: Beveled or square cut, Plastic capped.

Inspection & Certification

- Mill Test Certificate EN10204/3.1B

- Certification: ISO, API, PED, DNV, ABS, Lloyds etc.

- Third party inspection: SGS, BV, Lloyds etc.

Delivery

- Payment: TBA (To be agreed)

- Delivery: FOB / CFR / CIF

- Minimum order: 10 tons to 60 tons per size acc. to size or grade.

Seamless Steel Tubes for Oil Casing and Tubing API SPEC 5CT

Detailed Product Description

- Standard: API SPEC 5CT Standard of American Petroleum Institute

- Application: Seamless steel tubes for oil casing and tubing in oil wells

- Model N0. of steel tubes: J55, N80, L80, P110 etc

Tubing

Tubing is pipe used for the transportation of crude oil and natural gas from an oil or gas layer to the surface after drilling is complete. It is made to withst

and the pressure generated from the extraction process. Tubing is manufactured in the same way as casing, except that an additional process

known as "upsetting" is applied to thicken the pipes.

- The tubing production processing is similar to the process of casing production

- Tubing pipes typically have diameters of 60.3 mm to 114.3 mm.

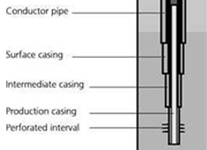

Surface casing

- Protects the well from contamination in shallow water and gas layers.

- Supports the wellhead equipment and sustains the weight of the other layers of casing.

Intermediate casing

- Isolates different layers of pressure to facilitate normal circulation of drilling fluid and protect the production casing.

- Intermediate casing facilitates the installation of blow-out preventers, anti-leakage devices and tailpipes in the well.

Production casing (oil string)

- It is the conduit through which oil and gas pass from a below surface reservoir.

- It protects the well and separates fluids into various layers.

For the manufacture of tubing, green pipes undergo an "upsetting" process to thicken the walls of the pipes. Apart from this step, the manufacturing of tubing and casing are identical. First, green pipes are threaded on each end. The threading is then inspected and, if necessary, rethreaded to ensure that the thread accurately connects to the coupling. The tubing and casing are strengthened by surface treatment and are subject to various inspections, including drifting and hydrostatic tests before they are coated and packaged into tubing and casing.